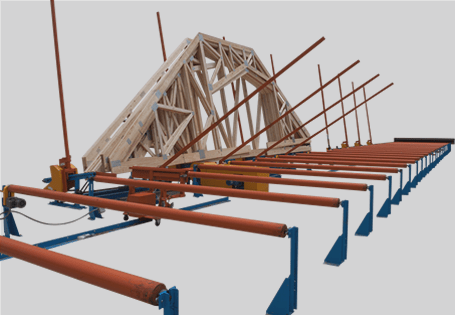

Horizontal

Stacker

Stack trusses horizontally (flat), reducing truss handling and minimizing the possibility of damage.

Features

Reduce Truss Handling

- Stacks trusses horizontally.

- Reduces truss handling and minimize the possibility of damage.

- Reduces the risk of injury commonly found in manual stacking procedures.

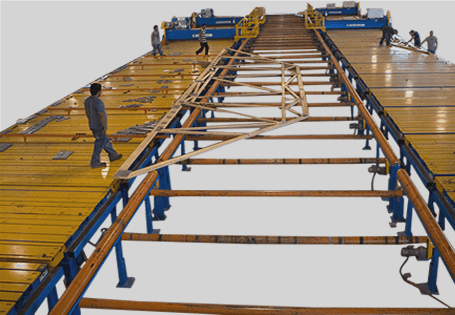

- Choose between the 2-transporter, 2-transporter tandem, or 4-transporter systems.

Horizontal Stacker Overview Video

Specifications

OVERVIEW

The Horizontal Stacker stacks trusses horizontally (flat), just like they will be shipped. This reduces truss handling which naturally results in less damage to trusses and fewer injuries to material handlers. Combine that with the Horizontal Stacker’s heavy-duty construction and compatibility with existing conveyor systems, and it is an ideal choice for post-fabrication handling. Reliable hydraulic operation with a built-in heater makes this different from other stackers! And a remote radio transmitter allows the operator to carry the control station throughout the plant and lumber yard for more flexibility and the ultimate in efficiency.

PHYSICAL DATA

| Components | Transporter(s) and HPU |

| Stacking Zones | 2 transporters = 2 stacking zones (1 on ea. side of conveyor), 4 transporters = 4 stacking zones (2 on ea. side of conveyor) |

| Motor | 10 hp per transporter |

| Motion Powered By | Hydraulic power |

| Hydraulic Reservoir | 40 gallons |

PERFORMANCE DATA

| Modes | Auto and Manual |

| Speed of Travel | 35-second cycle for multi-setup tables |

| Weight Capacity | 400 lb per transporter |

| Truss Length | 2-zone = 2 stacks, 18′ to 40′ 4-zone = 4 stacks, 18′ to 40′ OR 2 stacks, 18′ to 80′ |

| Truss Height | Up to 16′ |

| Transporter surface, from ground | 28″ to 74″ |

| HMI | Pushbutton station, touch screen, and remote radio transmitter |

ELECTRICAL DATA

| Electrical Specs | 208/230/460 VAC, 60 Hz, 3-phase |

Safety Data

| E-stops | Pushbuttons |

| Safety Compliance | UL (panels), OSHA |

| Indicators of Movement | Horn and beacon light |

| Labels | Bilingual or ISO |

- Choose your configuration: 2-zone or 4-zone

- Powered Stand-Alone Conveyors

- Interlocks to integrate with conveyor and finishing press

Download the Full Spec Sheet

Download PDFAutomation SUPPORT & RESOURCES

MiTek offers consulting, testing, documentation, design assistance and prompt customer service. Visit our Support, Training and Knowledge Base center for more information.

RELATED EQUIPMENT

View more of the most complete, reliable, and productive truss assembly manufacturing equipment in the industry.