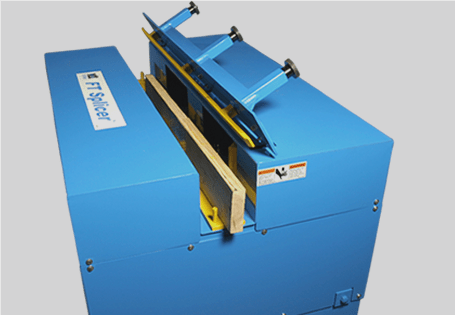

Finish Roller II

Completely embeds plates as the final step in a 2-stage pressing process.

Features

100% Plate Embedment

- Final step to a 2-stage pressing process

- Automatically increases torque for large plates

- Starts and stops as needed in automatic mode

Finish Roller II

Specifications

PHYSICAL DATA

| Roller Size | 24″ nominal OD |

| Throat Opening | Adjustable 1-3/8″ up to 3-3/4″ high |

| Motor | 10 hp |

| Guides | Guide rollers prevent bowing |

PERFORMANCE DATA

| Speed of Travel | 100′ per minute |

| Lumber Capacity | Any lumber 1-3/8″ to 3-3/4″ thick |

| Plate Embedment | 100% |

| Motor Control | VFD |

| Direction of Travel | Rollers rotate forward and reverse |

| HMI | Pushbutton panel, operates automatically in auto mode |

ELECTRICAL DATA

| Electrical Specs | 230 VAC, 60 Hz, 3-phase |

| E-stops | Pushbutton, pull-cord, light curtain (for end-eject only) |

| Safety Compliance | UL (panels), OSHA |

| Indicators of Movement | Horn and beacon light |

| Labels | Bilingual or ISO |

- Interlocks with any MiTek® stacker and Stand-Alone Conveyors

Download the Full Spec Sheet

Download PDFAutomation SUPPORT & RESOURCES

MiTek offers consulting, testing, documentation, design assistance and prompt customer service. Visit our Support, Training and Knowledge Base center for more information.

RELATED EQUIPMENT

View more of the most complete, reliable, and productive truss assembly manufacturing equipment in the industry.