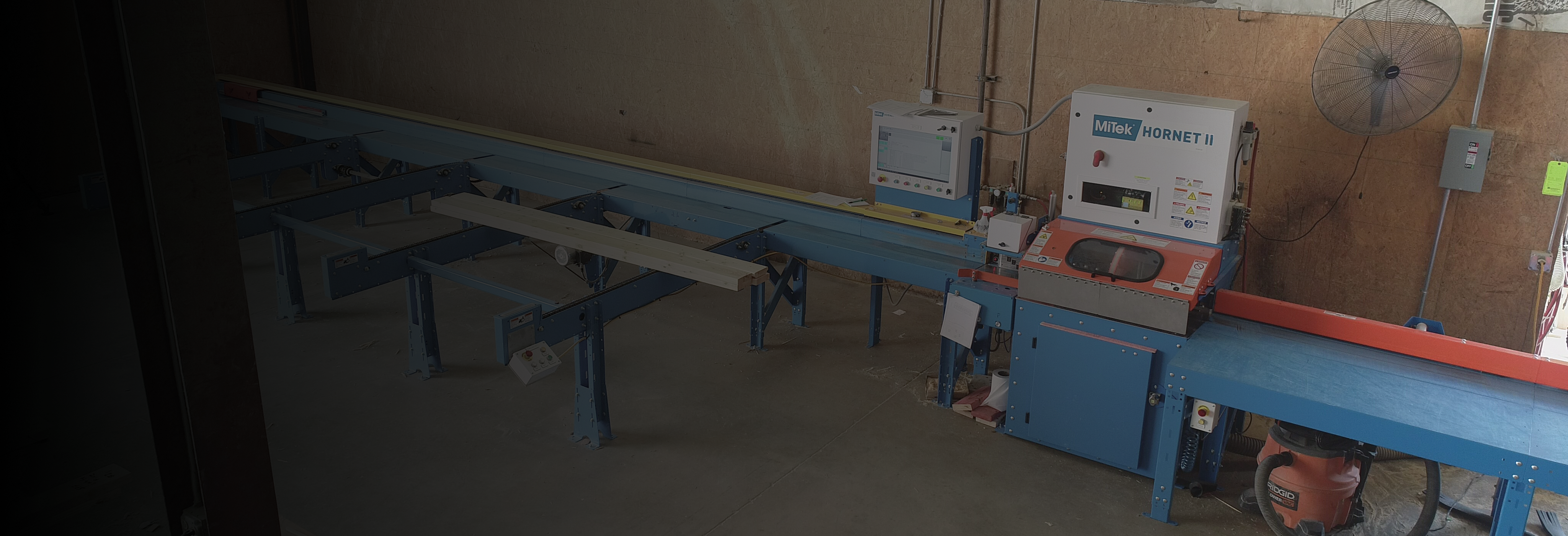

Hornet II Saw

Increase efficiency with high-speed layout, printing, and parts cutting

Overview

Cut and mark wall panels efficiently and accurately

The Hornet II™ Saw is a precision upcut saw optimized for wall panel production.

This next-generation saw cuts and labels multiple lumber pieces at once, enhancing productivity, reducing waste, and improving safety with minimal labor.

MiTek Hornet II Saw

Siemens Upgrade

The integration of Siemens with the Hornet II Saw results in a more robust industrial design and significantly improved user experience.

Extended saw life (10+ years)

Lower power consumption (up to 32% reduction)

Industrial touchscreen controls

Easier, more detailed, and improved diagnostics

Specifications

Features & Benefits

- NEW! Upgraded to REA JET printing, which provides ink level tracking, longer ink life, easier troubleshooting, and overall faster printing

- NEW! Extended infeed and added guard remove a pinch-point for safer operation

- Cut every part within the wall panel, including headers, sills, and blocking

- Increase efficiency by marking and cutting the top and bottom plates simultaneously

- Compatible with production software, including MiTek® Production

- Greater design and assembly team collaboration, with design intent embedded into the panel plate layout

- Bottom face printer to print complete bill of materials directly onto the lumber

- Reduce waste by automatically cutting scrap into useable lengths

- Fully automated infeed lumber conveyor and outfeed sweep feature

Additional Details

Software-driven saw automation

The up-cut saw, integrated with MiTek software, enables automatic cutting of top and bottom plates in one stroke. It features a fully automated infeed lumber conveyor for continuous cutting, with an outfeed sweeper for automatic removal of cut pieces.

High-quality printing

The plate layout edge printer allows for customizable printing on lumber, including a feature to print a BOM on the bottom face, enhancing assembly efficiency and accuracy without paper instructions. Plus, the part ID remains visible on stacked lumber, ready for job site delivery.

Automation SUPPORT & RESOURCES

MiTek offers consulting, testing, documentation, design assistance and prompt customer service. Visit our Support, Training and Knowledge Base center for more information.

RELATED EQUIPMENT

View more of the most complete, reliable, and productive truss assembly manufacturing equipment in the industry.