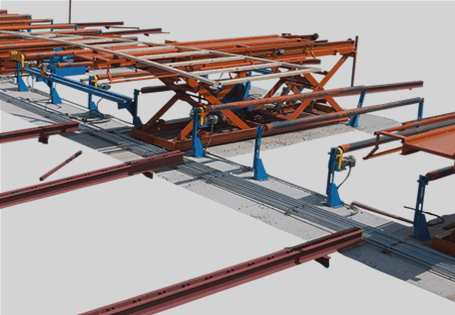

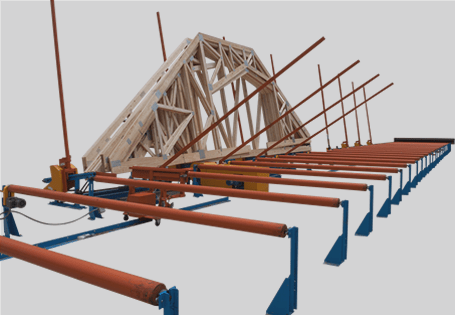

STAND-ALONE CONVEYOR

Transport large assemblies to the next stage in the building process.

Features

EASILY TRANSFER TRUSSES

- Reduces time spent on material handling tasks, increasing the productivity of your plant.

- Every second roller is powered to ensure smooth movement of the truss.

- Integrates with MiTek stackers and Finish Rollers to be fully automated if desired.

Stand-Alone Conveyor Overview Video

Specifications

OVERVIEW

The Stand-Alone Conveyors allow you to easily transfer trusses from your truss assembly areas to the Finish Roller, and from the Finish Roller to truss stackers. The conveyor system can greatly reduce time spent on material handling and increase the productivity of your plant. They are completely configurable to your workflow and footprint.

PHYSICAL DATA

| Components | 1 roller assembly consists of roller and legs. Every other roller has a motor attached. |

| Dimensions | 4-1/2″ OD x 14′ long (see Options) |

| Motor | 1/2 hp (see Options) |

PERFORMANCE DATA

| Rotation Speed | 100 ft per minute |

| Min. Truss Dimensions | The space between conveyor rollers is min. length |

| Max. Truss Dimensions | Length is unlimited; width of finishing press throat determines max. truss height |

| HMI | Pushbutton station |

ELECTRICAL

| Electrical Specs | 208/230/480/575 VAC, 60 Hz, 3-phase |

| 415 VAC 60 Hz, 3-phase |

Safety Data

- Pushbutton E-stop

- Bilingual or ISO safety labels

- Safety compliance: UL (panels), OSHA

Options

- Optional lengths: 3′, 4′, 6′, 16′

- Conveyor in parking area to stack trusses shorter than 10′

- Interlocks to integrate with conveyor and finishing press

Download the Full Spec Sheet

Download PDFAutomation SUPPORT & RESOURCES

MiTek offers consulting, testing, documentation, design assistance and prompt customer service. Visit our Support, Training and Knowledge Base center for more information.

RELATED EQUIPMENT

View more of the most complete, reliable, and productive truss assembly manufacturing equipment in the industry.